Working with residential heat exchangers requires more than just technical skill—it demands a strong commitment to safety. From carbon monoxide leaks to electrical hazards, the risks are real. As a technician, following essential safety protocols not only protects you but also safeguards the homeowners you serve.

Whether you’re inspecting, repairing, or replacing a unit, these heat exchanger safety tips will help you stay compliant, confident, and capable in the field.

Before You Begin: Set the Stage for Safety

1. Power Down the System

Before starting any work, always shut off power to the furnace at the main breaker. This prevents accidental shocks or unexpected equipment startup.

2. Wear Appropriate Personal Protective Equipment (PPE)

Never skip on safety gear. Your PPE should include:

- Steel-toed boots

- Gloves

- Safety glasses

- Long-sleeved shirts

- Hard hats or respirators, when needed

PPE protects you from chemical exposure, sharp components, and potential electrical hazards.

3. Use the Right Tools

Using improperly maintained or incorrect tools increases the chance of injury or equipment damage. Always check that your tools are:

- Designed for HVAC service

- In proper working condition

- Insulated (when applicable)

During the Job: Be Alert and Methodical

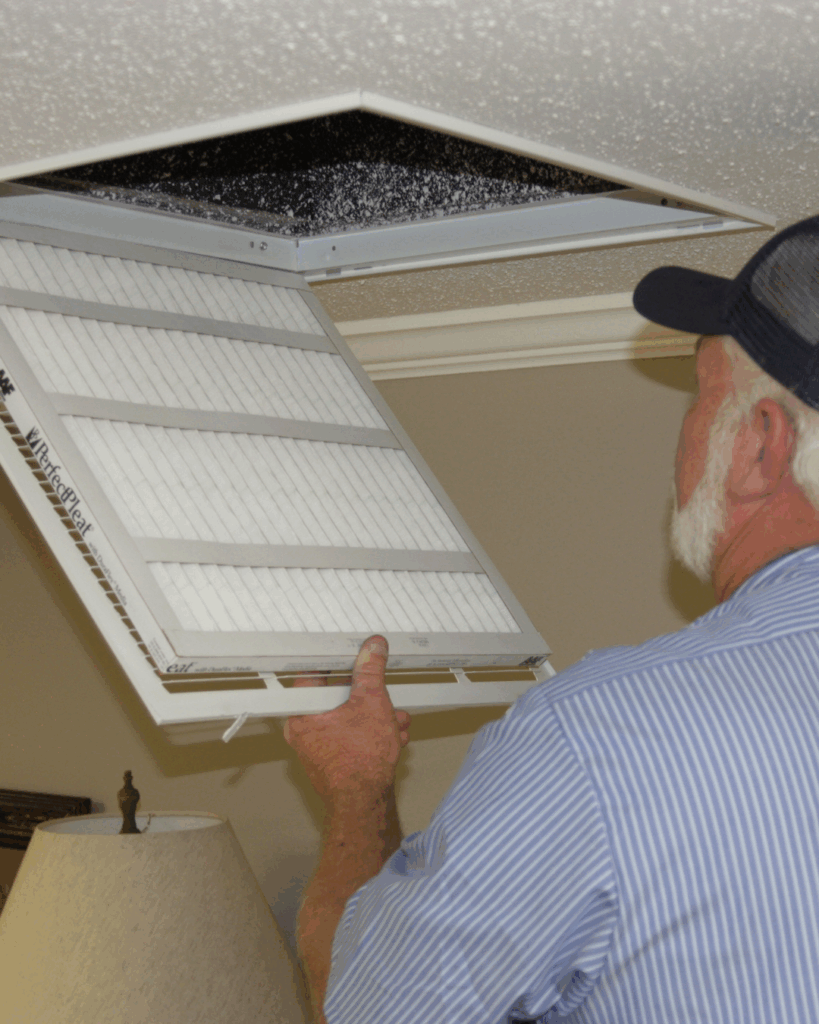

4. Perform a Visual Inspection

- Look for common signs of heat exchanger failure:

- Corrosion or rust

- Cracks or holes

- Discoloration or soot on internal surfaces

Pay special attention to stress zones, seams, and joints, where wear and tear often begin.

5. Test for Carbon Monoxide (CO) Leaks

A cracked heat exchanger can release carbon monoxide—an odorless, colorless, deadly gas. Use a combustion analyzer or CO detector to identify leaks. If present, shut down the unit immediately and inform the homeowner of the risks.

6. Handle Chemicals Safely

- Review all Safety Data Sheets (SDS) before use

- Store incompatible substances separately

- Label containers properly

- Always work in well-ventilated areas

HVAC chemicals can be corrosive, flammable, or toxic, especially when used in tight spaces without airflow.

7. Practice Ladder Safety

If you’re working in attics, crawlspaces, or rooftops:

- Position ladders securely

- Use fall protection when necessary

- Maintain three points of contact while climbing

A moment of caution can prevent serious injuries from falls.

After the Work: Leave It Safer Than You Found It

8. Check Smoke and CO Detectors

Recommend that homeowners:

- Test alarms monthly

- Replace batteries yearly

- Replace entire detectors every 5–7 years

A functioning CO detector can save lives if the unit develops future issues.

9. Educate the Homeowner

If you find a cracked heat exchanger, explain:

- Why it’s a safety hazard

- The importance of immediate repair or replacement

- How the issue affects indoor air quality, energy efficiency, and equipment lifespan

10. Commit to Ongoing Training

HVAC technology and safety standards evolve constantly. Stay updated on:

- Local codes

- Manufacturer recalls

- Industry best practices

Enroll in hands-on seminars and certification programs to remain sharp and safe.

Partner with Heat Exchanger Experts for Industry-Leading Training

At Heat Exchanger Experts, we don’t just teach inspection techniques—we prepare HVAC professionals to work safely and confidently in real-world conditions. Our training is designed to help you:

- Master defect identification

- Understand design flaws in older and modern exchangers

- Avoid life-threatening hazards like CO leaks

- Inspect dozens of field-tested heat exchangers in person

View Our Upcoming Classes to get started on the safest, most effective training in the HVAC industry. Get started today!

FAQ: Heat Exchanger Safety for HVAC Technicians

1. Why is heat exchanger inspection so important?

A cracked or corroded heat exchanger can leak carbon monoxide, leading to serious health risks or death. Routine inspections catch early signs of failure before they become hazardous.

2. How can I detect a CO leak in a residential furnace?

Use a combustion analyzer or electronic CO detector during furnace operation. Always cross-reference your readings with signs like yellow flames or soot buildup.

3. What should I do if I find a cracked heat exchanger?

Turn off the furnace immediately, inform the homeowner, and recommend replacement. Document your findings for safety and liability purposes.

4. Do I need specialized tools to inspect heat exchangers?

Yes. Inspection mirrors, borescopes, and combustion analyzers are critical for accurate diagnosis. Don’t rely on guesswork or visual inspections alone.

5. How often should I attend safety training or certification seminars?

At least once every 1–2 years. Regular training keeps your skills sharp and ensures you’re up to date with current codes, regulations, and equipment trends.

6. Is PPE really necessary for every job?

Absolutely. Even routine inspections can expose you to sharp metal, hot surfaces, chemical fumes, or electrical hazards. PPE is your first line of defense.